DUCTs system

pe-flex-eps

The PE-FLEX EPS air distribution system is an innovative way to combine the high aesthetics of installation with the speed of installation and excellent insulation of ventilation ducts.

The EPS system was developed to complement the PE-FLEX system for air distribution in the building. Thus, it is a modern alternative to the rigid spiro ducting and flexible flex ducting used to date, which are used to connect the recuperator to the distribution boxes and the intake and exhaust.

greater

insulation

resistant

on moisture

simple

installation

complete

system

thoughtful

construction

cheaper than

similar systems

- optimized size 45° knee enabling the creation of a short 90° knee

- walls as thick as 25 mm

- measure with centimeter graduation for easy cutting of the pipe

- possibility to use cut off pieces of pipe by using EPS coupler

- Dedicated bracket for stable support of the system

- EPP nipple allowing the system to be connected to flexible and rigid ducts

- possibility extension of the spigot connection stub

- embedded sockets streamlining installation and reducing the cost of installation

Complete system

to connect the recuperator

PE-FLEX EPS is a complete system for connecting a recuperator with an air intake and an exhaust, as well as with distribution boxes. By using built-in cups, it does not require additional fittings, making it cheaper than comparable systems on the market.

What components does the PE-FLEX EPS SYSTEM consist of ?

EPS PE-FLEX pipe Ø200/250 mm with a length of 100 cm

with integrated mounting cup and 25 mm thick walls

Rigid ventilation duct designed for air distribution in mechanical ventilation systems with recuperation. It is made entirely of EPS polystyrene with a high density of 40 kg/m³, which provides very good insulation properties of the cable along its entire length. The inner diameter of the cable is Ø200 mm, and the outer diameter is Ø250 mm. The length of the rigid ventilation duct is 1000 mm

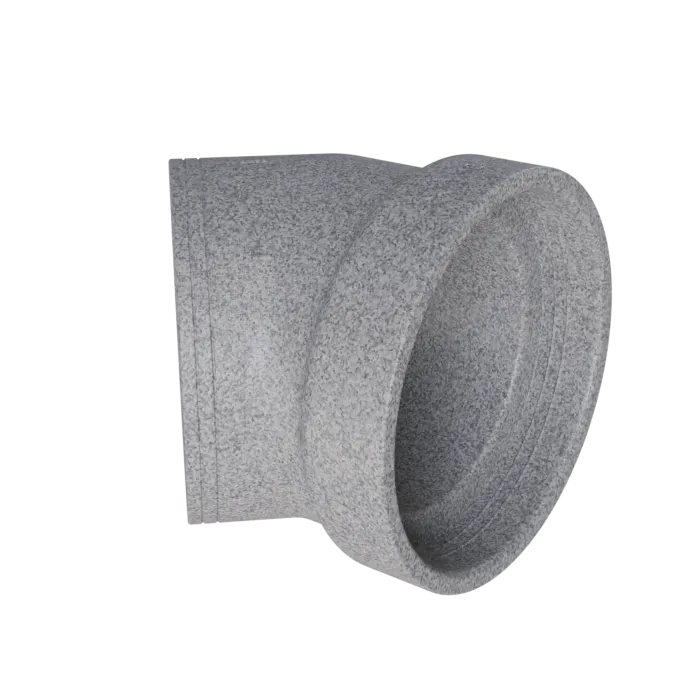

EPS PE-FLEX 45° elbow Ø200/250 mm

with the possibility of joining two pieces to form a 90° angle

The lightweight and durable EPS 45° elbow makes it possible to make bends and turns in the ventilation system. It is designed to create a compact elbow with a right angle and a 90° radius by connecting two fittings. Its smooth inner surface and special profiling minimize the resistance of the flowing air at the bend of the installation.

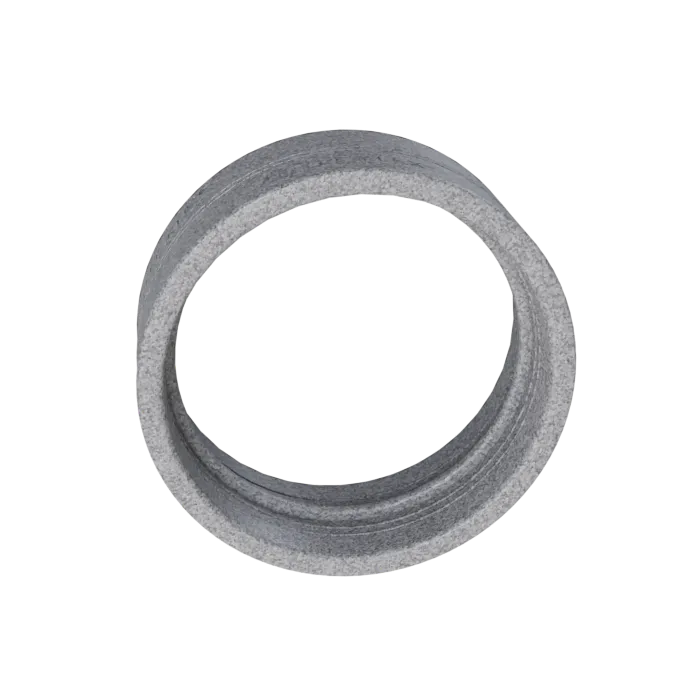

EPS PE-FLEX socket connector Ø250 mm

replacing the mounting cup and allowing the connection of two elements of the PE-FLEX EPS system

EPS coupler is used to connect two sections of EPS PE-FLEX pipe when you want to use a previously cut off section of pipe without a socket. This minimizes waste and the cost of the entire installation. In the same way, we can connect the cut piece of pipe to the elbow.

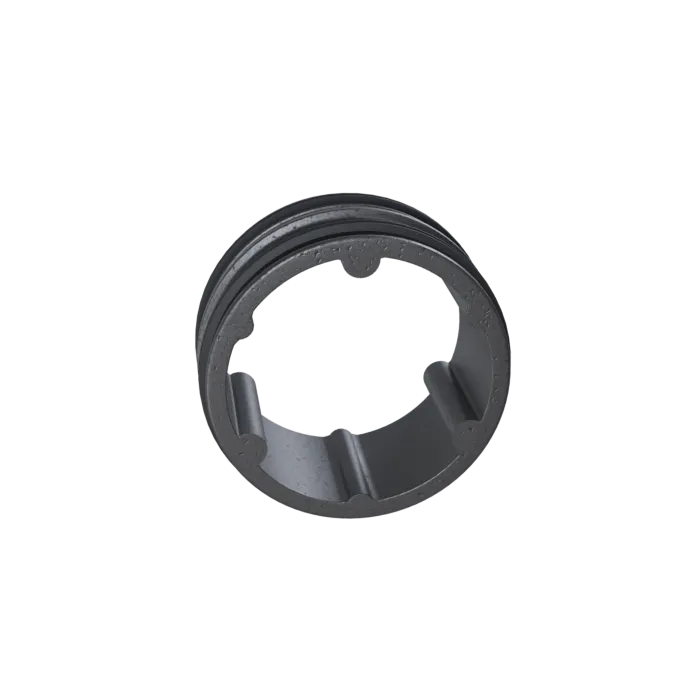

EPP PE-FLEX Nipple Ø198 mm

for the connection of flexible and steel channels with a diameter of Ø200 mm

The EPP nipple is made of deformation- and damage-resistant foamed polypropylene, which has very good insulation properties and is resistant to water. It allows you to make a “warm” connection without causing a thermal bridge of PE-FLEX EPS system components and standard flex and steel spiro ducts with a diameter of Ø200 mm.

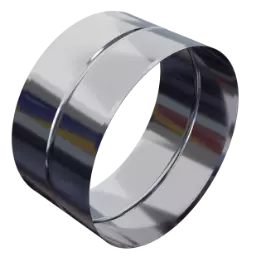

Ø250 mm stainless steel coupler

allowing connection of Ø250 mm air intake/exhaust grilles

The Ø250 mm coupler is made of weatherproof stainless steel and allows for connection to the bare end of the EPS PE-FLEX pipe of the intake and exhaust pipes with a diameter of Ø250 mm.

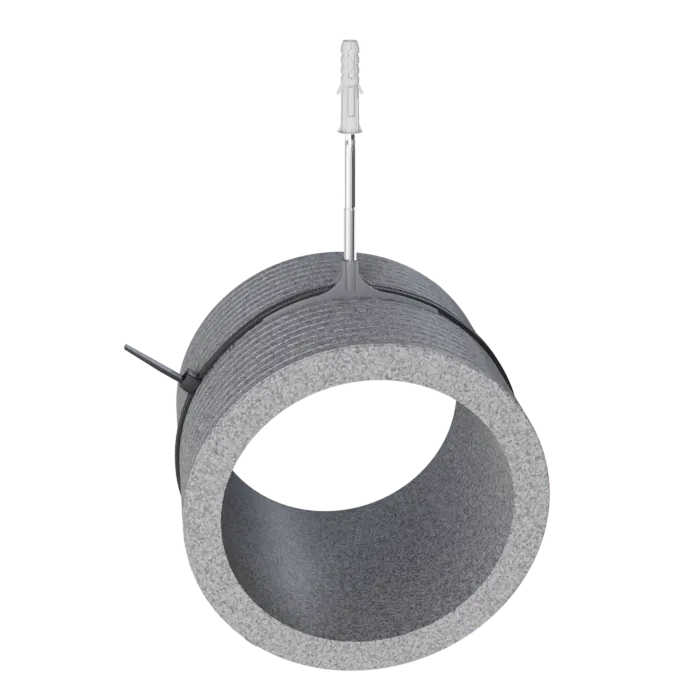

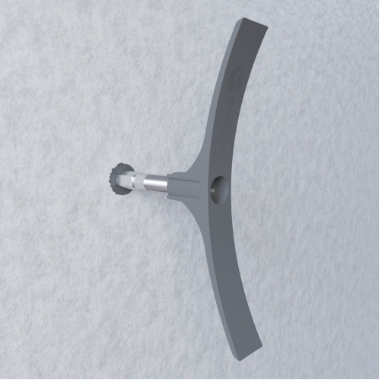

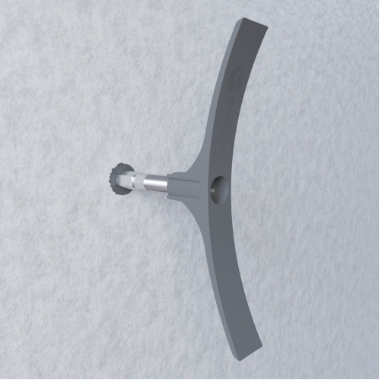

Holder for EPS pipes and fittings

facilitating the installation of the entire system

A dedicated bracket for the EPS system allows you to quickly and aesthetically install the entire system. Clamps are used to install the pipes, and the use of double-threaded screws of different lengths allows to move the EPS ducts away from the wall or ceiling. The handle is made of plastic and has great strength and flexibility.

Advantages of PE-FLEX EPS system

Up to 25% more insulation

and no thermal bridges

The elements of the system are made entirely of high-density EPS polystyrene, which guarantees very good insulation properties. Built-in gussets and system connectors guarantee continuity and tightness of insulation and no thermal bridges along the entire length of the ventilation system.

The EPS used in the production of PE-FLEX® EPS cables has up to 25% better insulating properties than cables insulated with wool or made entirely of EPP.

Connection of spiro pipes with 30 mm wool insulation

Flanged connection of EPS pipe

Resistant to water and moisture

and a guarantee of durability for many years

Forget about problems with insulation getting wet! Our PE-FLEX® EPS system, made entirely of moisture-resistant material, namely foamed polystyrene, guarantees not only extraordinary durability, but also the maintenance of stable insulation parameters for a long time.

The use of the innovative PE-FLEX EPS ventilation system is a guarantee of high quality that you can rely on. Discover a new quality in the field of making ventilation installations!

2 times faster installation of the system

and up to 8 times less weight of system components

Thanks to the use of insulating material and the lack of need for additional insulation, ventilation ducts made of EPS are an extremely practical solution. Not only do they provide optimal thermal insulation, but they also significantly speed up the installation process, saving time and costs.

In addition, their unparalleled lightness makes them much easier to transport and install than traditional wool-insulated steel ducts. As a result, ventilation installation from EPS ducts becomes not only faster and more efficient, but also more convenient for installers.

Thoughtful design

integrated cups and 25% lower installation cost

Thanks to integrated sockets, the PE-FLEX® EPS system, unlike competing solutions, does not require additional expensive connectors reducing the number of components needed, which translates into a reduction in material costs by up to 25%! In addition, the integrated gussets allow for quick and easy connection of fittings, which means an even lower installation price. This makes PE-FLEX® EPS more cost-effective, despite its high quality.

The use of precise

graduations every 1 cm make it easy to cut

and adjust the components to the needs of the installation, and specially built 45° elbows make it easy to create a compact elbow with a 90° radius.

Dedicated handle

for installation of EPS pipes

Our specially designed compact bracket is the ideal solution for professionals involved in the installation of ventilation systems with recuperation. Thanks to its clever design, you will easily and quickly make the connection of the recuperator with the intake and exhaust and distribution boxes using rigid insulated EPS ducts.

It optimizes installation time while guaranteeing the highest quality workmanship. Don’t wait any longer and choose the best solution for your ventilation system!

- Less resistance

airflow

The smooth inner surface of PE-FLEX® EPS ducting reduces the resistance of the flowing air compared to flex insulated ducting, thereby increasing the efficiency of the air handling unit and reducing energy consumption.

- Compatible

with other systems

The diameters of the PE-FLEX® EPS system have been selected so that it can be combined with both steel ventilation ducts and flexible flex ducts with a diameter of Ø200 mm using the system EPP nipple.

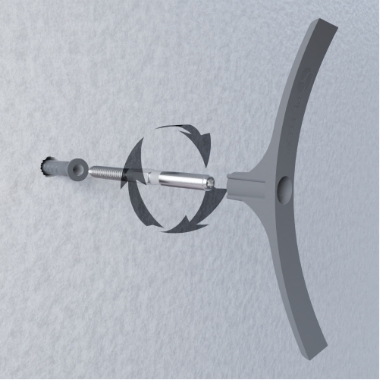

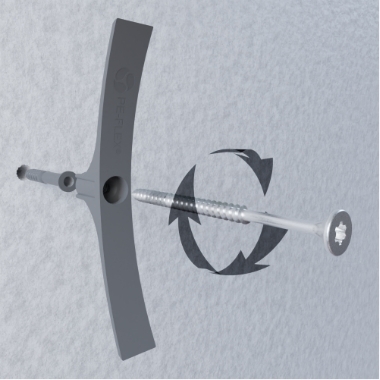

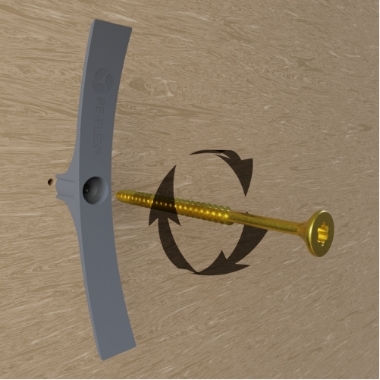

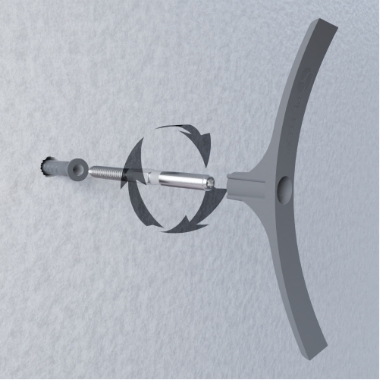

UNIVERSAL PE-FLEX® bracket installation for EPS system

Mounted to a wall or concrete ceiling using a wall stud and double-threaded screws. This mounting allows you to adjust the distance with the selection of a double-threaded screw of the appropriate length.

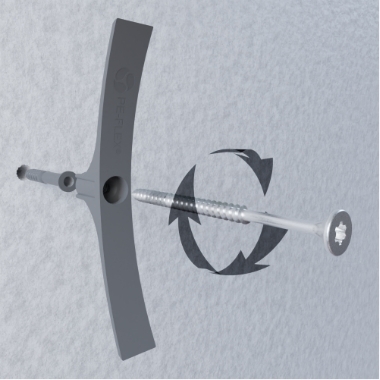

Direct mounting to a concrete wall or ceiling with a wall stud and screw. It allows faster installation of the bracket but without the ability to adjust the distance.

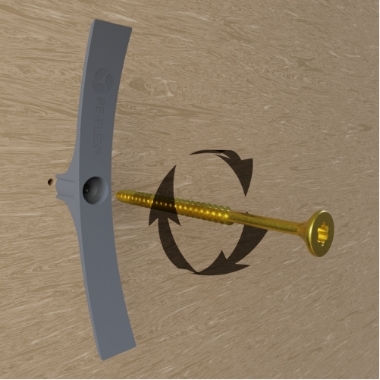

Quick and direct installation to a wooden structural member using only wood screw (without the ability to adjust the distance).

Mounted to a wall or concrete ceiling using a wall stud and double-threaded screws. This mounting allows you to adjust the distance with the selection of a double-threaded screw of the appropriate length.

Direct mounting to a concrete wall or ceiling with a wall stud and screw. It allows faster installation of the bracket but without the ability to adjust the distance.

Quick and direct installation to a wooden structural member using only wood screw (without the ability to adjust the distance).

ARCHITECT'S ZONE

A good installation starts with the design! Therefore, entrust its execution to specialists or become one yourself if you already have experience in this field. With our design guidelines, you will learn how to design the best-fit recuperation systems for the building, the contractor and the user.

The Architect’s Zone is an invaluable collection of tips, guidelines, standards and rules for designing mechanical ventilation systems with heat recovery.

ZONE

ARCHITECT

The couplers used with the KLIK system have built-in gaskets, ensuring high tightness of the connection, without the need for additional sealing. The couplers used with the KLIK system have built-in gaskets, ensuring high tightness of the connection, without the need for additional sealing.

ABC RECUPERATION GUIDE

If you are planning or installing mechanical ventilation, be sure to download the free guide!