Boxes

Expandable

Pe-Flex PP

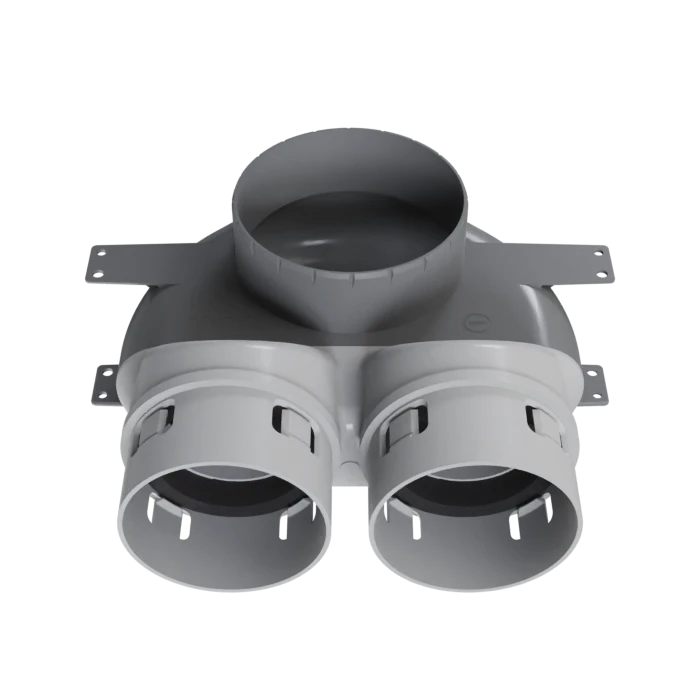

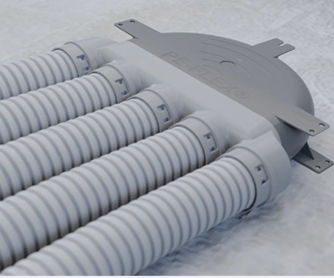

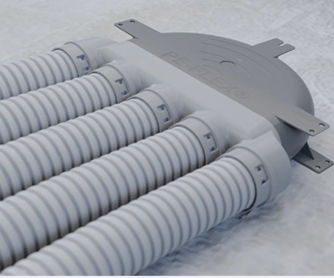

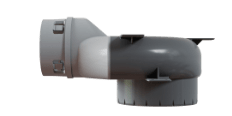

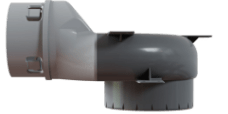

Expansion boxes are used to connect supply and exhaust anemostats to ventilation ducts, and their design reduces the speed and stabilizes the flow of air.

PE-FLEX PP boxes are constructed of durable plastic (polypropylene) with elasticizing additives, and its thick walls and use of welding technology ensure high durability and tightness for many years.

PE-FLEX plenum boxes have been refined for the absence of generated noise and low resistance to flowing air, and come in a number of variants for ceiling and floor installation.

System

KLIK

14

variants

into the system

Ø50 Ø75 Ø90

for anemostats

Ø 125 mm

100% to

recycling

certificate

PZH

- crate material suitable for 100% recyclable

- as much as 14 variants plenum boxes optimized for installation

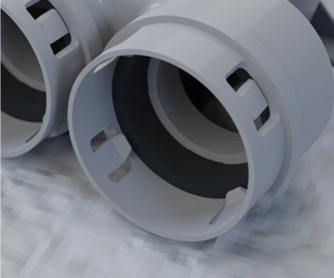

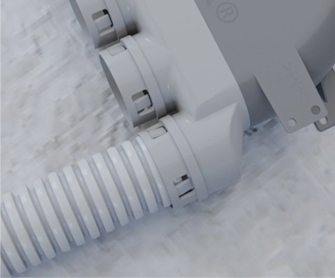

- built-in seals and latches in KLIK system allowing for fast, secure and tight installation of ventilation ducts

- integrated mounting brackets

- clear marking socket and nipple box

- aerodynamic shape Internal to guarantee low drag and no noise of flowing air

- low box body height of only 50 mm

- flexible plastic with elastomer additives and welded construction to ensure high tightness and durability of the boxes

PE-FLEX PP boxes number 1

In terms of ease and speed of installation!

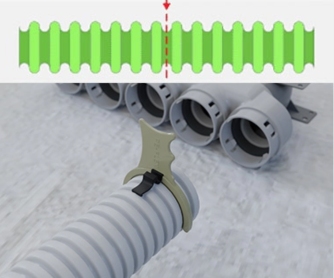

Quick installation on KLIK

KLIK means tight connection

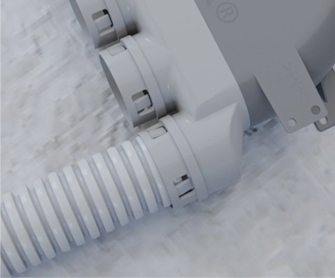

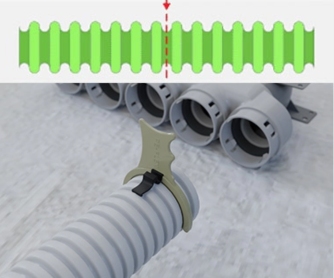

The use of couplers with the KLIK system allows very fast installation of ventilation ducts in boxes with a single movement! And this without the need to manually put gaskets on the pipes and use specialized tools. In addition, the KLIK system prevents the tube from dislodging on its own.

Installation Ventilation ducts

pe-flex® in boxes

1

Before inserting the cable into the spigot

cut its end evenly for

with the help of a special knife

2

Thanks to the gasket installed in the middle of the spigot, there is no need to apply it as a separate component to the cable

3

Insert the cut ventilation duct into the spigot of the box until you hear a “click!”

4

Insert the cut ventilation duct into the spigot of the box until you hear a “click!”

1

Before inserting the cable into the connection socket, cut the end of the cable evenly with a dedicated PE-FLEX cutter

2

Thanks to the gasket installed in the middle of the spigot, there is no need to apply it as a separate component to the cable

3

Insert the cut ventilation duct into the box coupler until you hear a distinct “click!” (make sure it has caught all four hooks)

4

Install the remaining PE-FLEX pipes in the plenum box in the same way

High tightness

Tight connection between the box and the pipe

The gaskets built into the couplers with the system on KLIK guarantee high tightness of the connection between the pipe and the box for many years and do not require additional sealing with tapes or silicone.

High durability

The boxes are resistant to site conditions

PE-FLEX PP expansion boxes are made of flexible plastic with elastomers, which gives them high strength and impact resistance, and protects them from damage during and after installation, when the installation is not yet secured. The welded construction adds extra rigidity, thus ensuring excellent tightness and durability, even when installed in the floor.

Welded construction

Choose a box for your needs!

PE-FLEX PP boxes are made up of modules welded together, which ultimately allow to obtain as many as 14 box variants. The welded construction of the boxes gives additional rigidity and provides excellent watertightness, which is lacking in folding models assembled by pressing or using gaskets, and which is so important, for example, when pouring concrete over them.

Hygienic certificate of PZH

Ensure healthy air in your home

Plastic expansion boxes are hygienically certified by the National Institute of Hygiene, which confirms the safe use of our products in domestic ventilation systems.

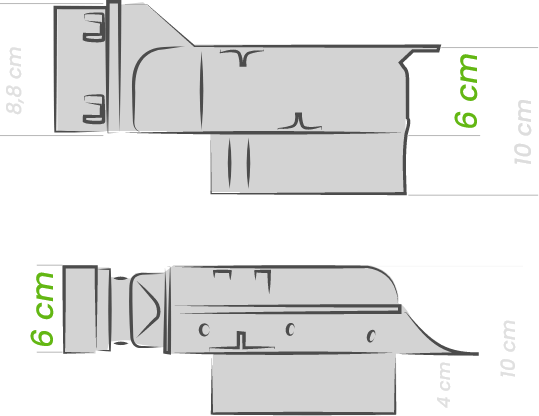

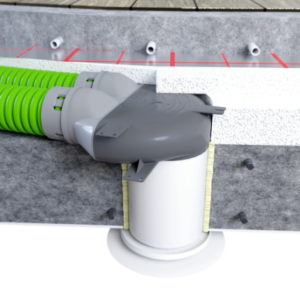

Small size

Only 6 cm body height!

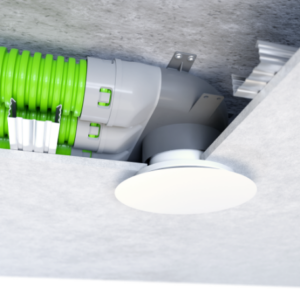

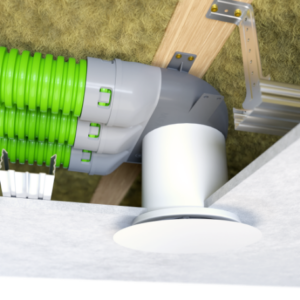

Thoughtful flat design of boxes with a body height of 6 cm makes it possible to hide the expansion boxes in the insulation layer under the screed or in the suspended ceiling.

In addition, 14 variants of expansion boxes make it possible to adapt the installation to the most demanding conditions, for example, installation of systems in old, renovated houses.

Small size

Only 6 cm body height!

Thoughtful flat design of boxes with a body height of 6 cm makes it possible to hide the expansion boxes in the insulation layer under the screed or in the suspended ceiling.

In addition, 14 variants of expansion boxes make it possible to adapt the installation to the most demanding conditions, for example, installation of systems in old, renovated houses.

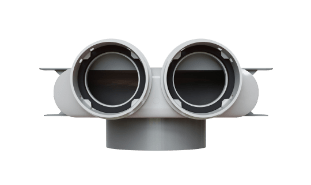

Types of PE-FLEX expansion boxes

Types of expansion boxes

PE-FLEX

Number and diameter of air ducts to be connected

PE-FLEX PP plenum boxes are offered in versions that allow the installation of PE-FLEX system ventilation ducts with outer diameters Ø50, Ø75 and Ø90 mm. The number of connected pipes should be based on the demand for the amount of air flow, and unused connection couplers can be plugged with the original PE-FLEX plugs.

5 x 50

Maximum flow rate

air: 60 m3/h

2 x 75

Maximum flow rate

air: 60 m3/h

3 x 75

Maximum flow rate

air: 90 m3/h

2 x 90

Maximum flow rate

air: 80 m3/h

Installation of boxes

PE-FLEX PP expansion boxes are available in floor-mounted versions – for installation of, among others. In the insulation layer of the ceiling, and with ceiling mounting – for installation over plasterboard buildings. Thanks to the special design, which allowed to obtain a low height of the body of the boxes, they can be successfully installed in thin floors and small ceiling buildings without reducing the size of the room.

5 x 50

floor assembly

min. Styrofoam layer of only 5 cm!

2 x 75 3 x 75

floor assembly

minimum layer of polystyrene foam 8 cm (recommended 10 cm)

2 x 90

floor assembly

minimum layer of polystyrene foam 9 cm (recommended 12 cm)

ceiling mounting

min. the value of lowering the ceiling 10 cm

ceiling mounting

minimum value of ceiling lowering

only 10 cm!

ceiling mounting

minimum value of ceiling lowering

13 cm

5 x 50

floor assembly

min. polystyrene foam layer

only 5 cm!

ceiling mounting

min. value

lowering of the ceiling

10 cm

2 x 75 3 x 75

floor assembly

min. layer

8 cm polystyrene foam

(10 cm recommended)

ceiling mounting

min. value

lowering of the ceiling

only 10 cm!

2 x 90

floor assembly

min. layer

polystyrene foam 9 cm

(12 cm recommended)

ceiling mounting

min. value

lowering of the ceiling

13 cm

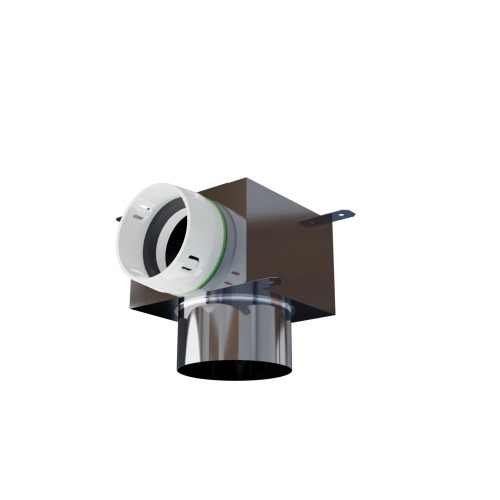

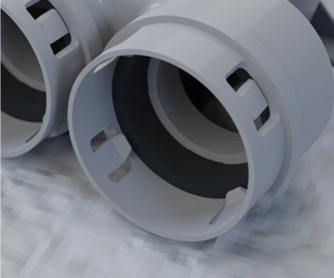

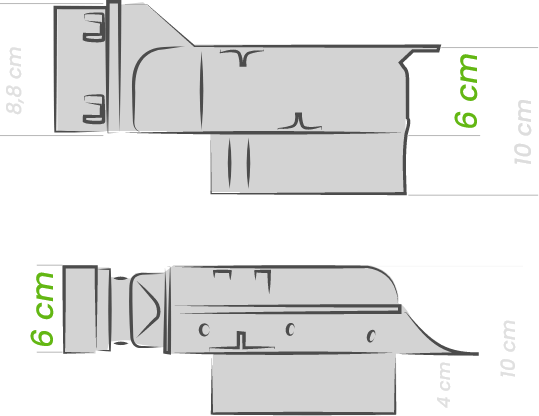

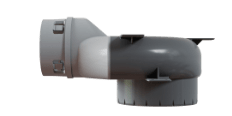

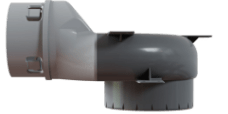

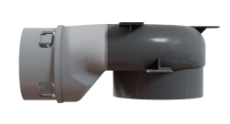

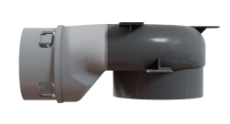

Socket and nipple boxes

All PE-FLEX PP plenum boxes are available in a variant with a nipple stub for extension or a coupler stub for mounting the anemostat directly into the plenum box – all so that you can match the right solution to any site situation.

Socket box

- For direct installation of Ø 125 mm ventilation valve

- When you are distributing the installation along the k-g frames or you care about slightly lowering the ceiling

- For the 2x75 and 3x75 box, the minimum ceiling lowering is only 100 mm, and for the 2x90 box only 130 mm

Nipple box

- Allows installation of a pipe extending the plenum box spigot

- When you mount the floor box on the ceiling or mount the box under the ceiling, but the ceiling lowering is greater than 130 mm

- The standardized outer diameter of the plenum box spigot is Ø 123 mm allows the use of a dedicated PE-FLEX extension or other Ø 125 mm ductwork

ASSEMBLY of plenum boxes

on the ceiling

overhead

under the roof structure

When installing the installation on the ceiling, it is important to remember to maintain the thickness of the insulation in which it will be hidden. It is also necessary to prepare holes in the ceiling with a diameter of min. Ø 132 mm under extensions of floor nipple expansion boxes PE-FLEX PP. Extensions should face (not protrude) the ceiling (also taking into account the thickness of the plaster).

When installing the installation under the ceiling, it is necessary to predict by what amount the ceiling will be lowered and select the PE-FLEX PP expansion box accordingly. For minimal lowering, a socket box will work, and above 14 cm a nipple box with a properly cut extension flush with the plasterboard. Carefully make a hole in the panel to install the anemostat frame without any problems.

The boxes can be mounted directly to a wooden structure. However, be sure to route the installation in the warm zone, under the ceiling insulation. If necessary, spread the pipes and boxes on the racks so that all the wool is above them. This will help you avoid heat loss. Also avoid running utilities in an unheated attic.

MONTAGE

expansion boxes

on the ceiling

When installing the system on the ceiling, remember to maintaining adequate insulation thickness, in which it will be hidden. It is also necessary to prepare holes in the ceiling with a diameter of min. Ø 132 mm under extensions of floor nipple expansion boxes PE-FLEX PP. Extensions should face (not protrude) from the ceiling (also taking into account the thickness of the plaster).

overhead

When installing the installation under the ceiling it is necessary to predict by what value the ceiling will be lowered and properly select the PE-FLEX PP expansion box. For minimal lowering, a socket box will work, and above 14 cm a nipple box with a properly cut extension flush with the plasterboard. Carefully make a hole in the panel to install the anemostat frame without any problems.

under the roof structure

The boxes can be mounted directly to a wooden structure. However, be sure to route the installation in the warm zone, under the ceiling insulation. If necessary, spread the pipes and boxes on the racks so that all the wool is above them. This will help you avoid heat loss. Also avoid running utilities in an unheated attic.

ARCHITECT'S ZONE

A good installation starts with the design! Therefore, entrust its execution to specialists or become one yourself if you already have experience in this field. With our design guidelines, you will learn how to design the best-fit recuperation systems for the building, the contractor and the user.

The Architect’s Zone is an invaluable collection of tips, guidelines, standards and rules for designing mechanical ventilation systems with heat recovery.

ZONE

ARCHITECT

The couplers used with the KLIK system have built-in gaskets, ensuring high tightness of the connection, without the need for additional sealing. The couplers used with the KLIK system have built-in gaskets, ensuring high tightness of the connection, without the need for additional sealing.

ABC RECUPERATION GUIDE

If you are planning or installing mechanical ventilation, be sure to download the free guide!