DUCTS

VENTILATION

PE-FLEX

The basic element of the PE-FLEX® ventilation system is PE-FLEX® ventilation ducts made of first-grade PE-HD plastic. PE-FLEX® double-layer ventilation pipe is designed to distribute fresh and exhaust air in the house and is used to connect plenum boxes to distribution boxes.

For added protection, the smooth inner layer has bactericidal, fungicidal and anti-static additives. PE-FLEX cables come in two variants: Standard and Spectra 1000.

Available in three diameters: Ø50, Ø75 or Ø90 mm

high

impact

Ag, Cu, +

product

antifungal

product

antibacterial

antistatic

certificate

PZH

- Almost 100% level of antibacterial and antifungal protection

- innovative Spectra 1000 additive inhibiting the growth of microorganisms

- The double-layer construction of the cables provides high compressive strength

- made of odourless and halogen-free raw materials

- available in 3 sizes Ø50, Ø75 or Ø90 mm

- high flexibility of wires allows free shaping, bending and routing of cables

- antistatic properties of the cables reduce the settlement and accumulation of dust in the pipes

- resistant to installation in the insulation layer of the ceiling and in the ceiling itself and poured in concrete

- no shape memory allows for aesthetically pleasing straight sections with fewer fixings

Properties

Bactericidal and fungicidal

More than 99% microbiological protection!

Mechanical ventilation is responsible for the continuous inflow of fresh outside air into the house and the removal of stale air, thus ensuring safe and healthy living conditions for all household members.

But how to make the ventilation system provide the highest standards of operation for many years of its life?

The solution is to use PE-FLEX ventilation ducts with the innovative Spectra 1000 coating, which has laboratory-confirmed bactericidal and fungicidal properties that guarantee no microbial growth in ventilation systems for many years.

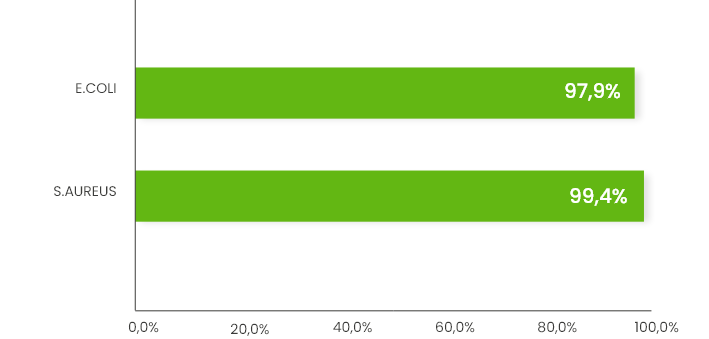

Reduction of bacteria in PE-FLEX Spectra 1000 pipes

Bacteria reduction rate after 24 hours of contact with the inner layer of the pipe

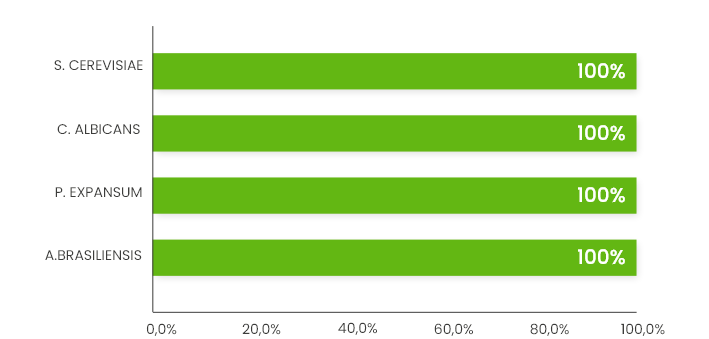

Effectiveness of reducing fungal growth in PE-FLEX Spectra 1000 conduits

Testing of fungistatic properties of the plastic in a 28-day test

Bactericidal coating

internal

30 year warranty

Phosphorescent under UV light, the inner wall of PE-FLEX pipes is made entirely of antibacterial and antifungal material, which protects it from the development of microorganisms on its surface. Additions of silver, copper and other microbial active compounds practically ensure the indefinite performance of the Spectra 1000 coating, which comes with a 30-year guarantee of effectiveness. Spectra 1000 is considered the best germicidal air duct additive on the market!

PE-FLEX Spectra 1000

vs. Standard

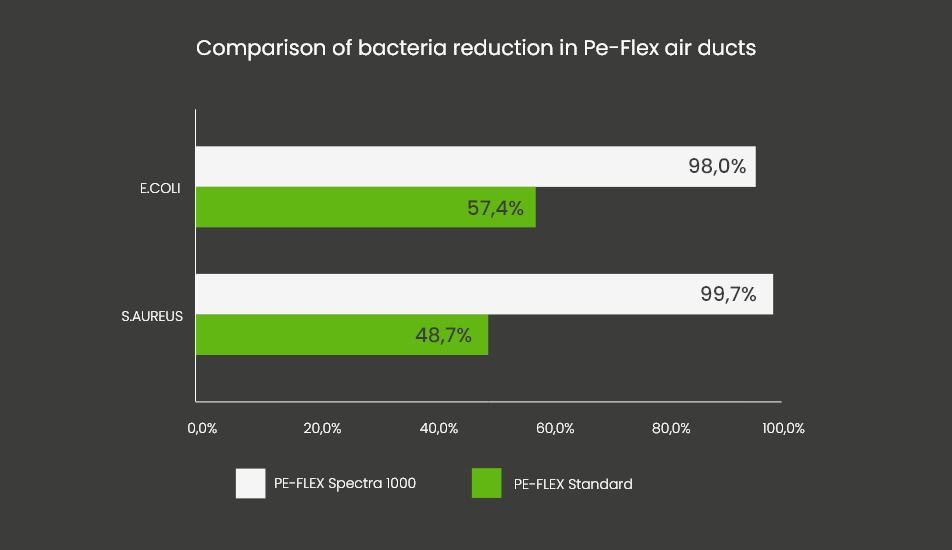

PE-FLEX ventilation ducts come in two variants that differ only in the properties of the inner coating:

– green Standard wires have bacteriostatic and fungistatic additives to provide basic microbiological protection.

– Spectra 1000 gray pipes with a coating that provides very high bactericidal properties and is the only one on the market with tested fungicidal properties of up to 100%.

Anti-static additives

smooth interior coating

Extensive experience in the industry has allowed us to create a pipe that combines an ideal compromise between the smoothness of the inner layer that maintains low airflow resistance and lack of dirt deposition, and the almost imperceptible notches that dampen air noise and ensure high flexibility of ventilation ducts.

To keep the entire ventilation system in the house as hygienic as possible, the inner layer has anti-static additives that reduce the settlement and accumulation of dust in the pipes.

High durability

Over 800N of compressive strength!

PE-FLE ventilation ducts even have more than twice the circumferential strength of other pipes on the market!

High durability ensures the safe installation of the system, without worrying about possible damage to it during the finishing of the building and for many years of use. It also allows the installation of ducts in the floors and ceilings of buildings and direct concrete pouring.

High flexibility

and no shape memory

Anyone who has installed a recuperation system at least once realizes how important the flexibility of the ductwork is to the comfort of its installation. The appropriate composition of plastics, the proportions of the pipe wall thickness and the appropriate width of the humps make it possible to make sharp bends of PE-FLEX pipes if necessary .

A very important feature of PE FLEX pipe is also the lack of shape memory, which makes it easier to run long and straight sections immediately after unrolling the pipe from the roll.

Self-extinguishing properties

Security for you and your home

To ensure peace of mind for residents of a house equipped with PE-FLEX recuperative ventilation system, all PE-HD plastic ventilation ducts have self-extinguishing properties.

In addition, for your family’s complete safety, Spectra’s gray PE-FLEX pipe is made of 100% halogen-free materials !

Hygienic certificate of PZH

Trust only proven products

PE-FLEX ventilation ducts are hygienically certified by the National Institute of Hygiene, which confirms the safety of their use in domestic ventilation systems.

Easy cutting

"made to measure"

with a dedicated PE-FLEX cutter

PE-FLEX is not only a ventilation system, but also a tool to facilitate the work of the installer. With the help of the PE-FLEX cutter, specially designed for corrugated pipes with diameters of 50, 75 and 90 mm, cutting flexible pipes is easier, faster and, most importantly, more accurate.

Quick and easy installation

special holder for PE-FLEX pipes

With a dedicated PE-FLEX holder for ventilation ducts, making installations is even easier and faster. The special design of the bracket makes it possible for even one person to mount pipes from the ceiling , and the lockable clip ensures that the pipe will not dislodge on its own. The ability to join brackets together also allows several pipes to be installed side by side using fewer studs or screws.

Three types of diameters

depending on the installation method

Ø50 pipe

Usually used in the insulation layer of the ceiling, when the ventilation system was not planned in advance and the standard thickness of the polystyrene foam layer in the floor was not increased.

Ø75 pipe

Remember! Increase the thickness of Styrofoam in the floor to a minimum of 8, and preferably 10 cm!

The most common diameter of ventilation ducts used in Poland. It is suitable both for installation in the insulation layer of the ceiling and for installation in suspended ceilings.

Ø90 pipe

The larger diameter of the pipe allows to transport more air over a greater distance. It is used most often in large and spreading ventilation systems.

Three types of diameters depending on the installation method

Ø50 pipe

Ø75 pipe

Ø90 pipe

Usually used in the insulation layer of the ceiling, when the ventilation system was not planned in advance and the standard thickness of the polystyrene foam layer in the floor was not increased.

Remember! Increase the thickness of Styrofoam in the floor to a minimum of 8, and preferably 10 cm!

The most common diameter of ventilation ducts used in Poland. It is suitable both for installation in the insulation layer of the ceiling and for installation in suspended ceilings.

The larger diameter of the pipe allows to transport more air over a greater distance. It is used most often in large and spreading ventilation systems.

Selection of the number of ducts depending on the amount of transmitted air

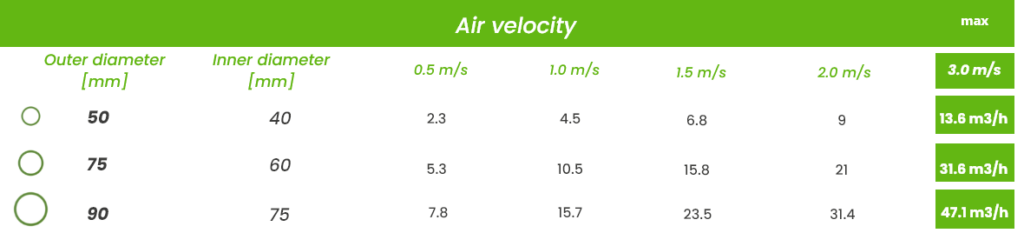

The amount of air transferred, and thus its velocity, is crucial in terms of the air resistance generated by the installation, as well as possible noise. Therefore, when designing a ventilation system, the number of strands of individual ventilation pipes should be adequately predicted, so that at maximum air flows the velocity in the pipes does not exceed 3 m/s.

Maximum air transfer rates in ㎥/h for one ventilation duct

Selection of the number of wires

depending on the amount of air transferred

The amount of air transferred, and thus its velocity, is crucial in terms of the air resistance generated by the installation, as well as possible noise. Therefore, when designing the ventilation system, it is necessary to adequately provide for the number of strands of individual ventilation pipes, so that at maximum air flows the velocity in the pipes does not exceed 3m/s.z

Maximum air transfer quantities in m3/h for one ventilation duct

Installation of ventilation ducts

PE-FLEX in the ceiling insulation layer

- Boxes and ventilation pipes are mounted directly on the ceiling.

- The installation is hidden in the insulation layer of the ceiling, for example, in Styrofoam, which should be at least the same thickness as the diameter of the pipe.

- A good solution is to lay a thicker layer of ceiling insulation and cover the entire ventilation system

- Underfloor heating can be installed directly over PE-FLEX® pipes - the two installations do not interfere with each other.

- When installing an expansion box, a hole should be made in the ceiling. From below, only the anemostat is visible, and the entire installation is covered with concrete screed and floor

Installation of PE-FLEX ventilation ducts in the insulation layer of the ceiling

- Boxes and ventilation pipes are mounted directly on the ceiling.

- The installation is hidden in the insulation layer of the ceiling, for example, in Styrofoam, which should be at least the same thickness as the diameter of the pipe.

- A good solution is to lay a thicker layer of ceiling insulation and cover the entire ventilation system

- Underfloor heating can be installed directly over PE-FLEX® pipes - the two installations do not interfere with each other.

- When installing an expansion box, a hole should be made in the ceiling. From below, only the anemostat is visible, and the entire installation is covered with concrete screed and floor

Installation of ventilation ducts

PE-FLEX in a suspended ceiling

Installation of PE-FLEX ventilation ducts in the suspended ceiling

- The entire system - wires and boxes should be installed under the insulation.

- Mounting on a suspended ceiling structure.

- Mounting directly to the ceiling (for example, concrete)

- Mounting with dedicated brackets or perforated steel mounting tape.

ARCHITECT'S ZONE

A good installation starts with the design! Therefore, entrust its execution to specialists or become one yourself if you already have experience in this field. With our design guidelines, you will learn how to design the best-fit recuperation systems for the building, the contractor and the user.

The Architect’s Zone is an invaluable collection of tips, guidelines, standards and rules for designing mechanical ventilation systems with heat recovery.

ZONE

ARCHITECT

The couplers used with the KLIK system have built-in gaskets, ensuring high tightness of the connection, without the need for additional sealing. The couplers used with the KLIK system have built-in gaskets, ensuring high tightness of the connection, without the need for additional sealing.

ABC RECUPERATION GUIDE

If you are planning or installing mechanical ventilation, be sure to download the free guide!

Buy directly from the manufacturer

PE-FLEX Standard Ventilation Duct